When it comes to electrical work, precision and efficiency aren’t optional — they’re essential. Whether you’re wiring a new panel, repairing old connections, or assembling custom harnesses, one task stands at the foundation of it all: wire preparation. This is where a wire stripping machine becomes an invaluable tool for electricians and technicians alike. Modern wire stripping machines combine speed, accuracy, and safety in a way that manual stripping simply can’t match. Let’s explore how these machines help professionals save time, improve quality, and boost productivity on every project.

The Importance of Efficient Wire Preparation

Wire stripping might seem like a small step in a large workflow, but it plays a critical role in ensuring reliable electrical connections. Cleanly stripped wires ensure proper conductivity, reduce the risk of short circuits, and make installations more durable.

Manual wire stripping, however, comes with drawbacks — it’s slow, physically demanding, and often inconsistent. Using handheld tools can easily nick or damage the conductor, leading to poor connections or costly do-overs. That’s why more professionals are switching to automated wire stripping machines for dependable, high-quality results.

Boosting Productivity and Efficiency

Time is money, especially for electricians and technicians who handle repetitive wiring tasks. Wire stripping machines can process dozens — even hundreds — of wires in the time it would take to strip a few manually.

By delivering precise and uniform cuts, these machines eliminate rework and reduce the risk of wiring errors. For high-volume operations, such as electrical workshops, manufacturing facilities, or cable recycling centers, the productivity gains are substantial. Even small-scale electricians can save hours per week simply by automating this essential step.

Improving Accuracy and Quality

One of the biggest advantages of wire stripping machines is precision. Unlike manual methods, they strip insulation cleanly without cutting or damaging the conductor beneath. The result is consistent, smooth wire ends ready for crimping, soldering, or terminal connections.

This precision is particularly valuable for technicians working on complex systems — from automotive wiring harnesses to control panels and circuit boards. Every clean cut helps maintain signal integrity, reduce electrical resistance, and ensure long-lasting performance.

Enhancing Safety and Reducing Fatigue

Manual wire stripping can take a toll on the hands and wrists, especially after hours of repetitive motion. It also carries a higher risk of injury from slips or sharp tools. Wire stripping machines solve both problems.

With automated or semi-automatic operation, technicians can strip wires quickly and safely without constant strain. The ergonomic benefits are immediate: fewer repetitive stress injuries, less fatigue, and more consistent output even during long workdays. For professionals handling large wire bundles, this translates to a safer, more sustainable workflow.

Versatility for Different Wire Types

Modern wire stripping machines are designed for versatility. They can handle a wide range of wire sizes, materials, and insulation types — from copper and aluminum to coated and shielded cables. This flexibility makes them ideal for electricians, automotive technicians, and electronics repair specialists alike.

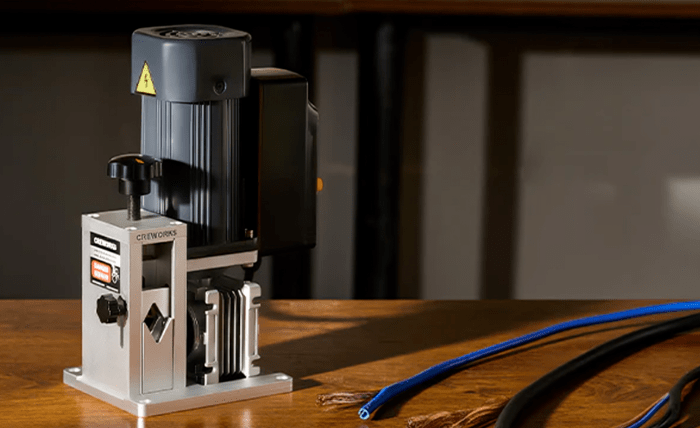

For instance, Creworks wire stripping machines are known for their adaptability and robust construction. Whether you’re stripping small gauge wires for circuit boards or thick cables for recycling, Creworks models can adjust easily to suit the task, offering the perfect balance of precision and durability.

Cost Savings and Long-Term ROI

Although a wire stripping machine may seem like an upfront investment, it quickly pays for itself. By reducing manual labor, preventing wire waste, and increasing output, it helps businesses save both time and money in the long run.

For small workshops or independent electricians, these savings add up quickly. Faster job completion means more projects, higher revenue, and fewer costly mistakes. In short, a reliable wire stripping machine isn’t just a convenience — it’s a smart business decision.

Choosing the Right Wire Stripping Machine

When selecting a wire stripping machine, it’s important to consider your specific needs. Key factors include wire size range, automation level, portability, and material compatibility.

Manual machines are great for low-volume use or field work, while electric and automatic models suit busy workshops and industrial environments. Creworks offers a variety of models designed to meet professional demands, combining high efficiency with user-friendly operation.

Conclusion

For electricians and technicians, every second and every cut counts. A wire stripping machine helps ensure that both are used wisely. By improving accuracy, boosting productivity, and enhancing workplace safety, these machines transform the way professionals handle one of the most repetitive — yet crucial — tasks in electrical work. If you’re ready to work smarter, not harder, consider investing in a dependable wire stripping machine like those from Creworks. It’s a small upgrade that delivers big results — helping you complete projects faster, safer, and with a level of precision your clients will notice.