Steel laminations play a crucial role in how motors and generators perform under real duty. These metal stacks shape magnetic flux paths to drive efficient energy conversion in systems. Expert solutions in manufacturing and design help ensure cores meet high fidelity demands for aerospace roles. In this context, aerospace performance relies heavily on precise electric machines that respond well under stress and temperature.

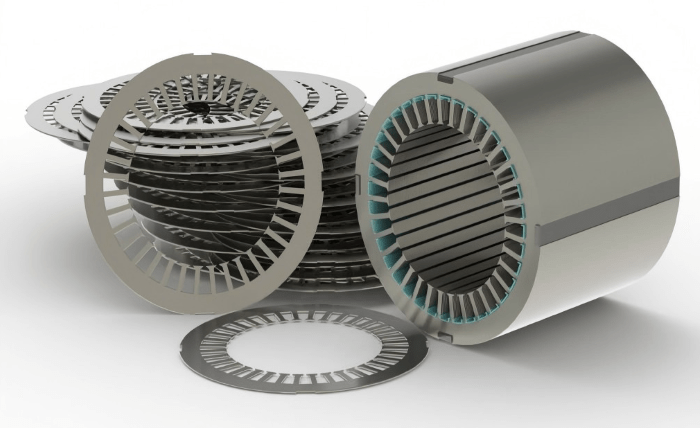

Electrical steel laminations serve as the heart of core structures in motors, generators, and control systems. That core structure reduces loss, improves reliability, and supports durable field behavior under strain. Targeted engineers and system architects seek better core materials to meet strict weight and power demands. This article offers insight and guidance to help readers apply these solutions wisely.

1. Cut Energy Loss And Boost Efficiency

When a motor uses magnetic core stacks, it avoids large eddy currents inside the cores. That design choice reduces wasted power losses and pushes more useful energy into rotation. Aircraft systems benefit because less electric heat is produced, and efficiency stays high in mission phases. Aerospace motors and generators run cooler and last longer with that loss reduction advantage.

This lamination approach also helps magnetic flux travel more cleanly through core paths without detours. That clarity of flux means less wasted magnetic energy and more precise field control. In aircraft applications, efficiency gain matters because energy budgets are tight and margins are small. The lamination layers truly help the entire propulsion and auxiliary system perform better.

2. Sharpen Magnetic Behavior

Electrical steel offers strong magnetic properties that support rapid changes in field direction in motors. The good conductivity of this steel supports fast flux build-up and decay cycles in rotor motion. In flight systems where loads shift frequently, magnetic stability and control remain crucial for system integrity. The laminations ensure fields respond without much delay or loss under diverse conditions.

This precise magnetic behavior ensures torque delivery stays smooth and stable across wide operational windows in flight. Pilots and onboard control computers depend on consistent motor response for delicate maneuvers. With proper grades of lamination steel, the magnetic path remains reliable and strong under stress. That reliability reinforces confidence in advanced electric actuators, propulsion assemblies, and other mission-critical aerospace power systems.

3. Improve Mechanical Strength With Light Weight

Stacked laminations help provide structural support while avoiding heavy solid steel sections that reduce performance. In aerospace applications, every gram counts, so lamination cores offer a high strength-to-weight balance. Motor rotor and stator assemblies remain rigid under centrifugal load without overburdening the aircraft structure. That strength offers protection against vibrations and thermal cycles in flight conditions.

The layered steel also resists warping and keeps its shape steady under varied temperatures and continuous stress. That strong robustness ensures alignment and mechanical clearances remain precise and safe. Engineers appreciate that level of consistency because maintenance demands stay lower throughout an aircraft’s entire operational life. The balance between light weight and long-term durability becomes a key performance indicator.

4. Permit Custom Material Choices Under Extreme Conditions

Designers can select from silicon steel, nickel alloys, or cobalt-iron alloys, which basically depend on precise mission demands. Each material provides a unique mix of heat resistance, corrosion resistance, and magnetic strength within the core. For instance, cobalt-iron alloys resist wear and high temperatures in harsh aerospace areas. Nickel laminations preserve magnetic permeability across moderate flux levels and reduce losses within essential operating systems.

Thin-gauge silicon steel suits many electric drive cores where weight and loss matter most. Designers can match steel grade (for example, M15, M19, M36) to mission frequency and load demands. That freedom gives system architects tools to tune performance instead of relying on one generic steel. The result feels much more tailored and robust to extreme flight scenarios.

5. Enable Sharper Thermal And Magnetic Control Via Post-Processing

After laminations take shape, a careful anneal heat treat relieves internal stress and fosters magnetic quality. That thermal process helps enlarge grain structure and reduce magnetic hysteresis in core steel. The result keeps losses low even under shifting temperatures across altitude and load regimes. Aerospace hardware gains stable magnetic traits regardless of environmental conditions.

Thermal control in such post steps also enhances overall uniformity across the entire lamination stack to prevent weak zones. That uniformity allows magnetic flux to move more evenly and avoid hotspots or any degraded electromagnetic performance. The stability remains crucial in long mission cycles that face extended temperature swings across varied environments. Such control in manufacturing ensures predictable and dependable performance within actual high-demand flight hardware.

Aerospace systems depend on components that combine precision, strength, and consistency under harsh operational conditions. Electrical steel laminations offer a dependable foundation for motors and generators that demand lasting reliability and power. Their durability transforms efficiency goals into real performance gains that matter in high-value aerospace applications. Connect with trusted experts today to explore advanced electrical steel laminations tailored for your next innovation.